Megatronic Battery Monitoring Solution

Megatronic Power Systems has developed their industrial battery monitoring system (BMS) to offer protection, reliability and economic advantage to battery power storage systems.

The system is a smart and flexible product thanks to its well engineered innovative design. It is suitable to be used for any type of rechargeable batteries and specifically engineered around the latest lithium-ion technology.

Increased Reliability . Reduce Costs . Increase Efficiency . Increase Safety .

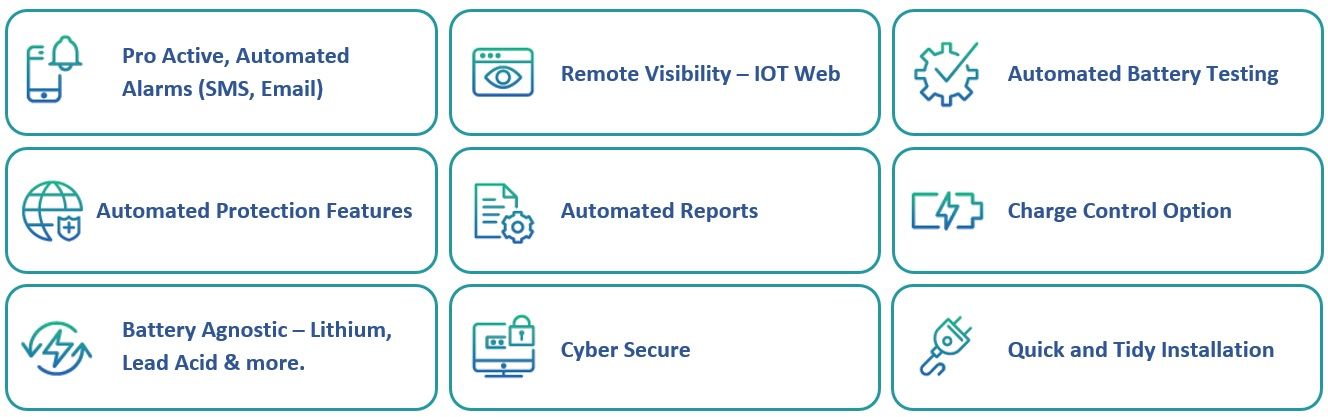

Features:

Clink this link to Download Brochure.

Patented Technology

Designed and Manufactured in Australia - Local Services, Local Support.

Battery & Cell Monitoring Systems - Perth

Megatronic Power Systems is a leader in Lithium Battery Monitoring and Remote Monitoring services in Perth. We have developed an industrial battery monitoring system (BMS) that delivers optimal protection, reliability and economical features to support battery power storage systems for commercial and industrial purposes.

We are proud to offer Australian manufactured and designed battery systems with patented technology and quality local support to our broad range of clients. With increased efficiency, safety and reduced costs over time, you can’t go wrong with our state of the art industrial battery systems.

Our extensive experience in automation and power control systems is a key factor in our success. Furthermore, we take a pro-active approach to identify all current and potential risks to your operations, providing you with rapid solutions to extend the functionality of your automation and workplace battery systems.

Whether you need cell balancing maintenance or cell voltage monitoring, we can deliver professional solutions to ensure maximum safety and longevity for all your battery monitoring needs.

What is the cost of Battery Failure to you?

All batteries will fail, it’s just a matter of time.

Most battery systems or UPS systems are utilised as critical backup power supplies. The reason that they are in place is to offer reliability to your operations.

Battery faults are usually detected when a battery system is called into action, but fails on demand. When you think there is a healthy 100% power storage, the reality can be that you have limited power available or none at all.

One faulty / deteriorating battery cell in a battery bank can destroy all the cells in the bank quite easily and quickly. Batteries are vulnerable when overcharged or reach the low discharge level.

✓ 80% of UPS failures are due to undetected /problems.

✓ 17% of failures are caused by Human error.

The impact of battery failure can be catastrophic:

- Reliability of Operations : A battery system failure normally has a huge knock-on effect resulting in downtime to operations. The physical cost of the downtime can result in millions of dollars of lost production.

- Fire : Overcharging or undercharging a single battery in a battery bank can result in catastrophic failure, explosions and battery fire.

- Cost of Asset : Replacing battery systems is expensive. Some batteries today are designed to last 20+ years. If they are not monitored and maintained properly, they will fail unnecessarily with a poor return on investment.

Do you know WHEN your batteries will fail?

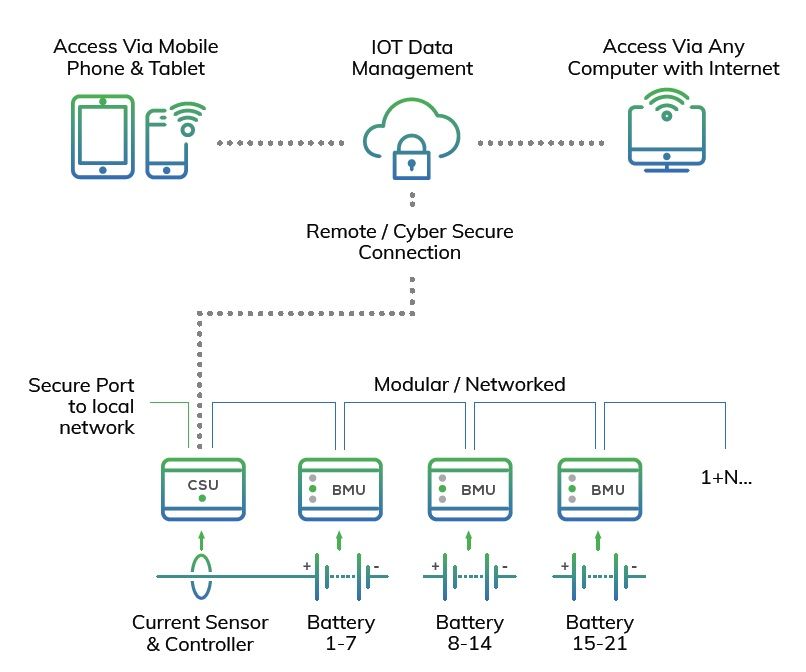

System Overview - How it Works.

The solution has been developed to detect the state of charge (SOC) and health state of each individual battery cell on a bank of batteries. It detects individual battery faults prior to failure and raises warning before the whole bank of batteries suffers.

The BMS also automatically tests each battery at regular intervals and logs the data ensuring that maintenance tasks are completed accurately and as efficiently as possible.

The BMS can also be utilised to control the charge of a battery power system.

The cyber secure, IOT web-based user interface ensures that the right information is extracted

from the batteries and displayed in a clear, easy to understand format with simple instruction on how to rectify any highlighted issues.

Control systems can also read and display the data through standard industrial communication protocols.

There are also volt free contacts which are pre programmed to receive hardwired alarms from the BMS.

SMS and Email alarms can be sent to maintainers, along with monthly reports.

The battery monitoring units are modular and can be linked together to monitor an infinite number of battery cells. The system is completely scalable.

Critical Battery Information.

Individual Battery Monitoring :

Individual battery monitoring offers 100% certainty on the health of a battery bank. A string of batteries is only as strong as the weakest battery in the string. If one battery suffers problems or has reduced capacity, then the entire string is limited to the performance of that compromised battery.

✓ Individual Voltage Measurement :

Overcharging or undercharging batteries can quickly destroy them or lead to the batteries exploding and causing a fire. It is also very important to keep the voltage of each battery in a sting / bank balanced and as close to equal as possible. This will ensure the capacity and efficiency of the string / battery bank.

✓ Individual Resistance Measurement :

The resistance of each battery is a good indicator of the age and health of the battery. Degradation can be tracked and the life expectancy of the bank can be projected more accurately.

✓ Individual Battery Charge % Calculation :

Monitoring individual voltage and resistance, combined with string current allows for an accurate calculation of ‘Individual Battery Charge %’. This allows the operator to easily identify the ‘weakest link’.

String Current :

Monitoring the current of the string / battery bank means the energy delivered or used can be

accurately determined. This can also help identify issues with the battery charger.

String Voltage :

This can indicate that the charger is powered on and performing.

Ambient Temperature :

It is very important to know and control the environment batteries are operating in to maximise equipment life.

Artificial Intelligence :

A trend graph can show clear signs of stress on certain batteries within a string or battery bank. Megatronic BMS algorithms can quickly filter through historical information and pin-point issues with the batteries.

Applications :

- Switch-room Control Power ( Power Generation and Distribution);

- Rail Signalling Battery Power Systems;

- Mobile and Fixed Communications;

- Large Scale Renewable Battery Storage;

- Residential Battery Storage;

- UPS Systems for Hospitals and Datacentres.

- All Solar / Battery Storage Systems.

- Diesel Generator Batteries – Protect Start-up.

- Power Generation Backup Power Systems.

- Battery Charger Control Unit.

- Solar Power Monitoring (Power Generation and Usage Tracking)

Control Systems Engineering, Electrical Engineering & Industrial Automation

At Megatronic Power Systems, we pride ourselves on delivering innovative Lead Acid Battery Monitor solutions on time and within budget. If you currently have an inadequate battery management set up, it can lose its effectiveness much quicker, minimising its performance over time. This is commonly seen in both DC and AC UPS systems.

No matter what kind of technical problems you’re facing, we can step in and help with all your battery monitoring concerns. From technical design and implementation to setting up the right operator interface, our specialist engineering team will ensure every detail is completed using precision methods to extend the life of your battery performance.

We pride ourselves on delivering quality results for our clients, businesses and industries throughout Perth, resulting in increased productivity and minimal downtime on the job.

For more information on our battery monitoring solutions in Perth, give Megatronic Power Systems a call today on (08) 9477 3919 or email: info@megatronicpower.com with your online enquiry and we’ll get back to you as soon as possible.